Assisted Handling

Deploy ANATERGOARM™ at your factory

The Assisted handling division manufactures and develops assisted manipulators and tool-support arms for industrial manufacturing such as automobile and aerospace manufacturing. These hyper-redundant ergonomic arms simplify jobs that involve repetitive tasks or tasks where heavy tools are used, especially in tight and confined spaces.

Assisted Handling products

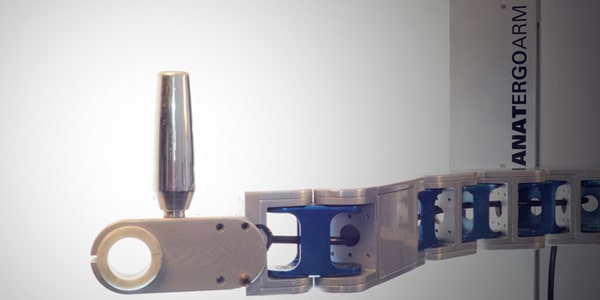

ANATERGOARM AEA-15

The ANATERGOARM AEA-15 is a modular ergonomic arm that increases worker safety and productivity while using heavy tools in repetitive tasks, thanks to its no gravity load design.

View detailsANATERGOARM AEA-50

The ANATERGOARM AEA-50 is a tool-support snake-arm for hand-held tooling up to 50kg. It excels at tasks in tight spaces and bends around several obstacles while carrying heavy loads.

View detailsANATERGOARM AEA-50M

The ANATERGOARM™ AEA-50M with the CutterGripper™ loads and unloads more than 100 types of heavy milling cutters from the automatic tool changers of CNC milling and lathe machines and holds them in place for adjustments. It also holds or rotates the disc cutter for users to add and remove cutting edge inserts. The arm lets you slide loads effortlessly and glide through confined and tight spaces in complete comfort without power consumption.

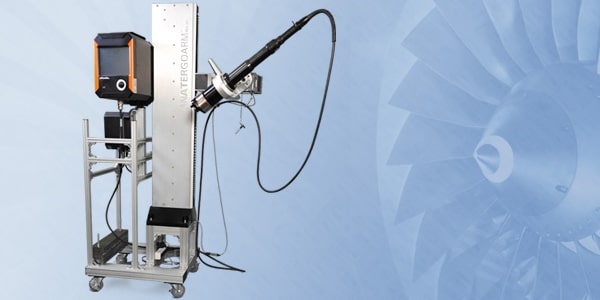

View detailsANATERGOARM TMA-500

The ANATERGOARM TMA-500 is a manual modular manipulator arm specialized for operations in hydro-electric turbines. It allows a single user to navigate tight spaces and obstacles while carrying payloads of 500kg.

View detailsDeploy ANATERGOARM™ at your factory

Maximize Worker Productivity

The Assisted handling division seeks to solve two problems common in industry today: problems associated with repetitive tasks and with maintenance and repair in tight and confined spaces. Repetitive tasks in manufacturing plants have been known to cause R.M.I. such as carpal tunnel, and lead to reduced worker efficiency and costly medical procedures. Maintenance and repair jobs that are performed in constricted spaces are typically complex due to the inflexible and bulky size of most assisted manipulators. This is typically solved by significantly increasing the manpower for a job, and rearranging manipulators numerous times to be able to work in different hard-to-reach places. Also, many applications involving spaces with limited manoeuvrability are unsuitable for rails and cable balancers, due to the limited flexibility of these manipulators.

Robotics Design’s ergonomic assisted manipulator arms help simplify tasks involving both repetitive tasks and tasks where maintenance and reparation jobs are performed in limited spaces, while increasing productivity. The torque-absorbing modular design of these arms allows users to use heavy tools such as pneumatic or hydraulic equipment and virtually eliminate kickback, and workers are able to move this equipment around any obstacle effortlessly.

The hyper-redundancy and modularity of these ergonomic arms allows workers to use them in tight spaces where obstacle avoidance and small size are critical, such as the automotive industry or wind turbine reparation. This maximizes human resources by allowing a single arm to be used for the complete application, without having to displace the arm’s base. The high payload carrying capacity and modularity of these arms allows accessories of almost any size, weight, or shape to be attached, and accessories can be removed and replaced easily, or locked into place.

Robotics Design knows that special challenges require special tools, and therefore we customize our ergonomic arms to suit any application on demand. They can also be made mobile on rails or a cart depending on the application.